- No. of Employees: 450

- No. of R&D Staff: 35

- No. of QC Staff: 20

- No. of Production Lines: 8

- Annual Output Value: USD 15 Million

- Peak Productivity: 100 to 150 Sets of Kitchen Cabinet Combinations Daily

- Management System Certification: ISO9001:2008, OHSAS18001:2007, ISO14001:2015

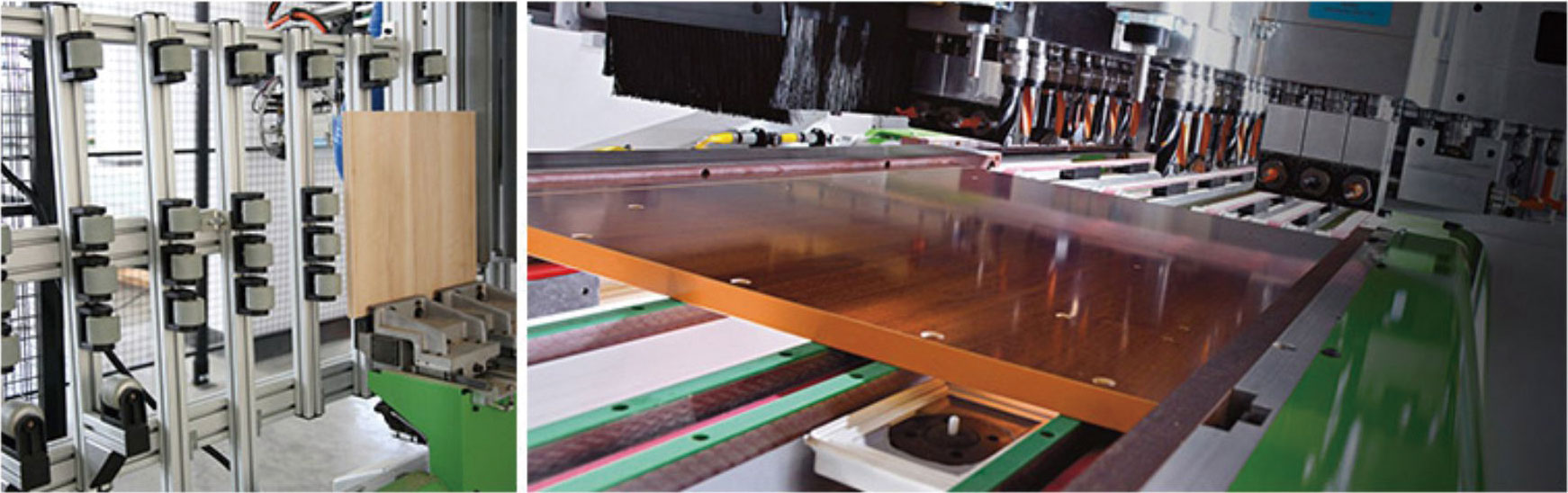

Milling Machine

We are using the most advanced and efficient plate cutting equipment, which could cut up to 7 pieces of plates at the same time. The machining accuracy could reach the level of ± 0.1 mm. This assures the accuracy of every single piece of plate and makes the whole final product accomplish the perfect design proportions.

Edge Banding Machine

The devices of production which has the highest accuracy in China are here in YALIG for edge sealing work. They have multiple features such as auto-heating, follow-up pressure, edge sealing, edge cutting, rough milling, finish-milling, arc milling, polishing all within the same production line. These make sure the edge sealing process accomplished with strong sealed and smooth edges, which creates more delicate products.

Row-holing Machine

Our row-holing machine is fully controlled by computers for positioning and feeding. It is able to create complex shapes that normal devices are not able to accomplish. It also has higher accuracy and efficiency than other similar type of machine. Plates manufactured through this can be joint perfectly and also with high strength.

CNC Production Devices

- BIESSE CNC Holing Machine

- BIESSE Production Center Machine

- Aikefa (Flycut) CNC Carving Machine

- Hold CNC Edge Sealing Machine

- Homag CNC Edge Sealing Machine